Bespoke Design Consultancy

Designing electronic controls for world-leading brands

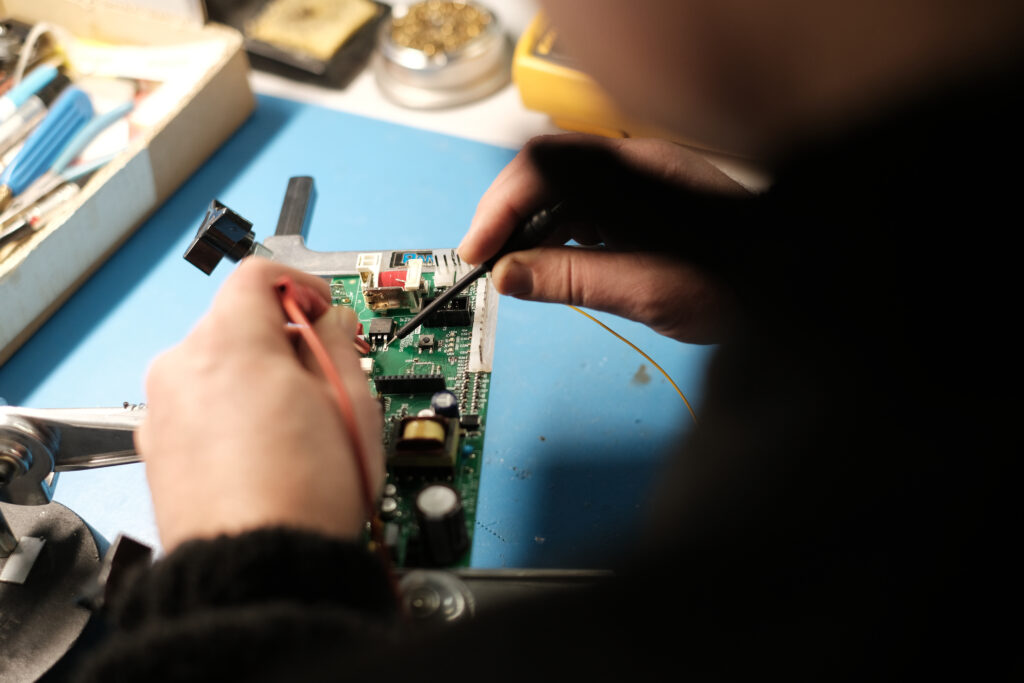

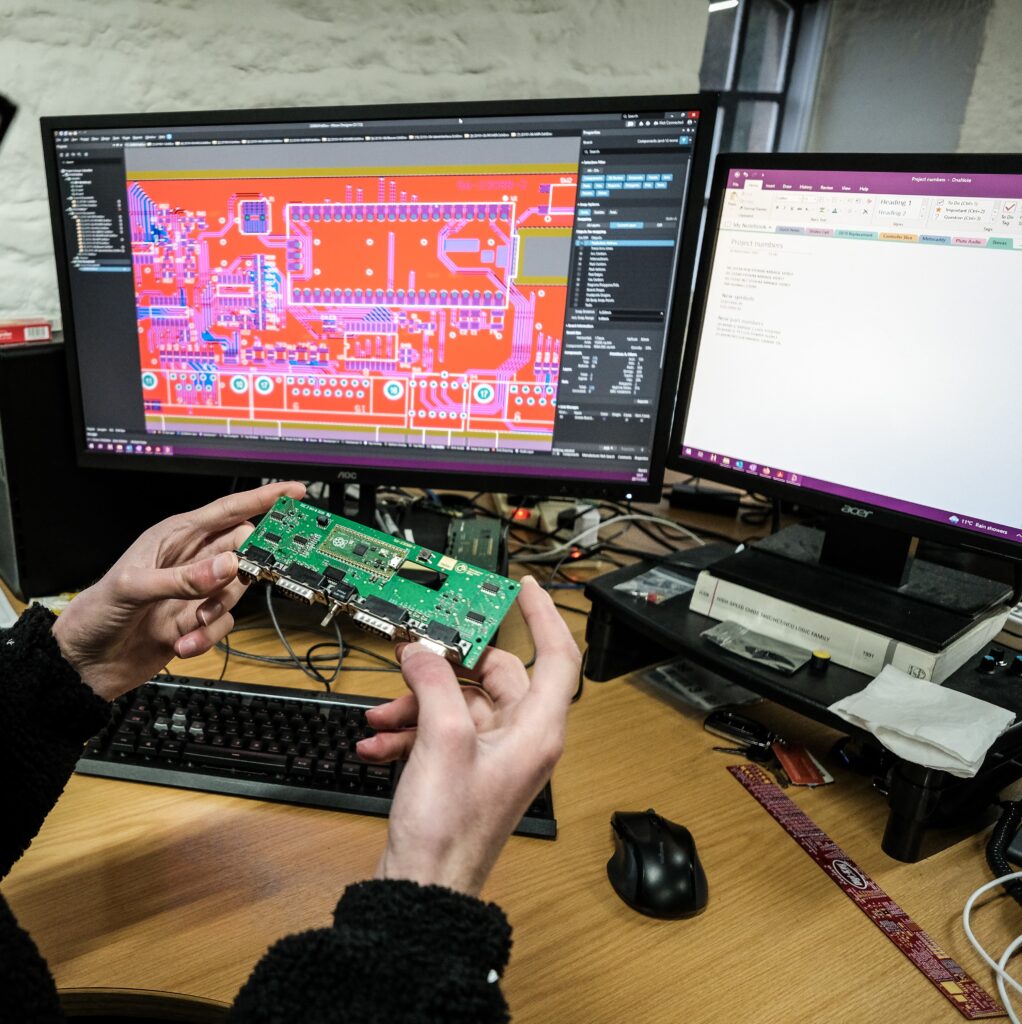

Heber has been designing electronics for over 35 years, and has experience in a wide range of industries. We have the capability to manage a complete development, from product conception through to the final product and production.

What ever stage your project is at, we can help with individual elements such as feasibility studies, software design, PCB layout or just advice. Our consultancy services can be as flexible as you need, for as long as you need. All current projects and developments with all clients are confidential.

Our case studies give a good example of the full range of industries we have worked in. We worked with both giant multi-nationals and fledgling start-ups. All have benefitted from our experience in delivering brilliant solutions to often complex engineering problems.

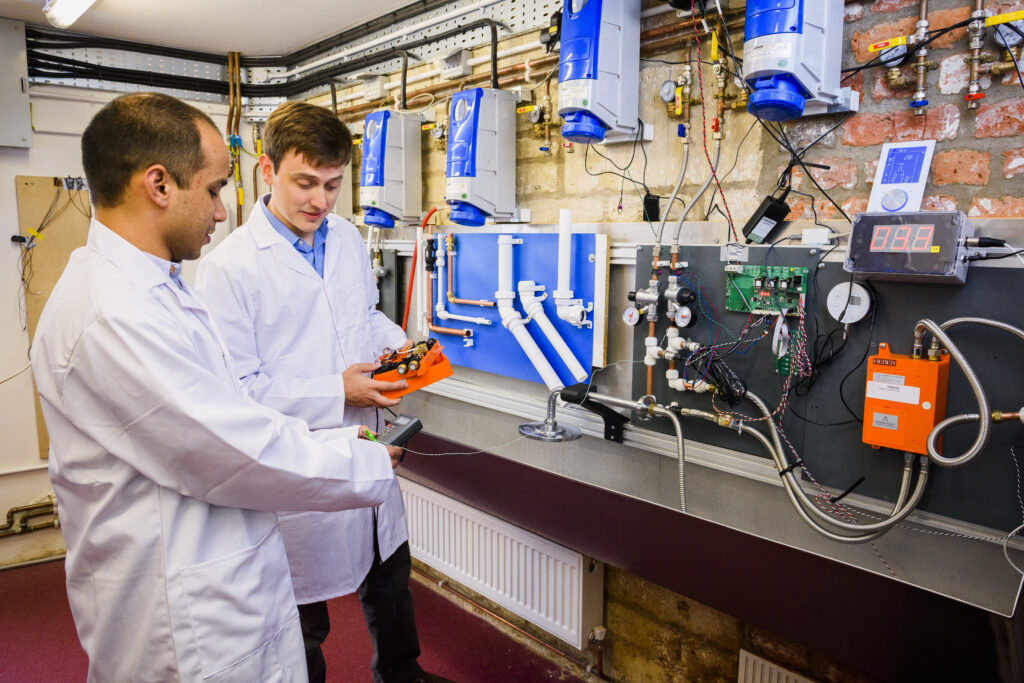

Refreshing Electronics Design

Heber have a long and extensive history of sensing, controlling and manipulating fluid based control systems. From showers and washing machines to high pressure steam cleaning and leak detectors. Our systems include use of solid-state’ proportional valves to mix fluids or control temperatures and flow rate, innovative real time control loops that detect and calibrate the boiling point of water on installation, smart technology and detection of legionella in water.

We have also helped to fix problems on existing projects which have run into problems, such as ensuring prototype showers met the requirements of the BEAB Care Standard.

We have over 30 years’ experience working in the white goods industry with some of the industries biggest names.

Solutions for Safe and Independent Living

Heber has worked in collaboration with different industries to create systems and devices which allow for safe and independent living.

We have worked with Homeserve Labs to create ‘Leak Bot’, a smart water leak detector. Leak Bot not only reduces water waste but it also warns of small leaks before they cause significant water damage to homes. We have also created devices which use thermal and AI technology to warn consumers of potential cooking fires. This was recently included in e.ons ‘homes for living’ scheme.

Our experience in water flow technology has enabled us to work with companies who create accessible washing facilities.

Low powered data collection

Heber have extensive experience with telemetry and low power operation even in challenging conditions.

These low powered options can be used on a wide range of products, and because we design and test everything in house, we can make any adjustments needed.

Custom Gaming controls

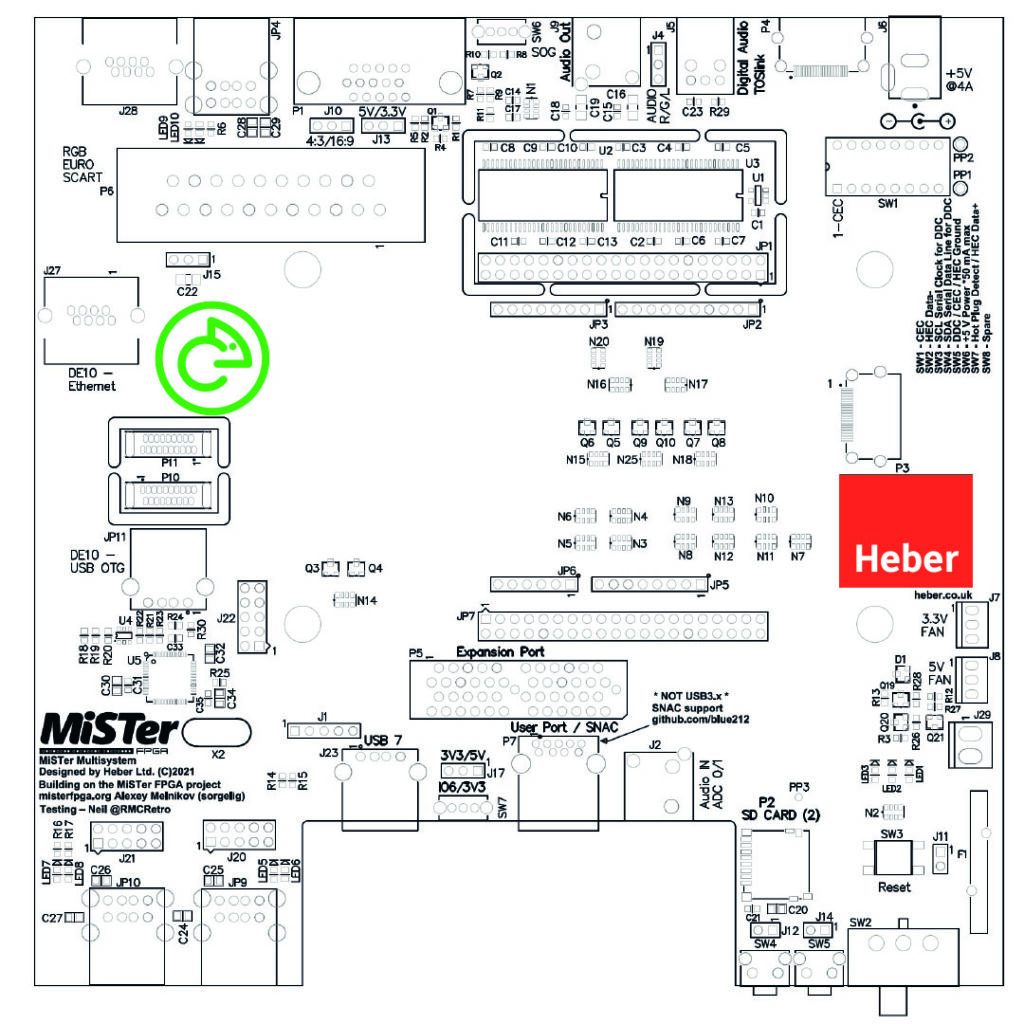

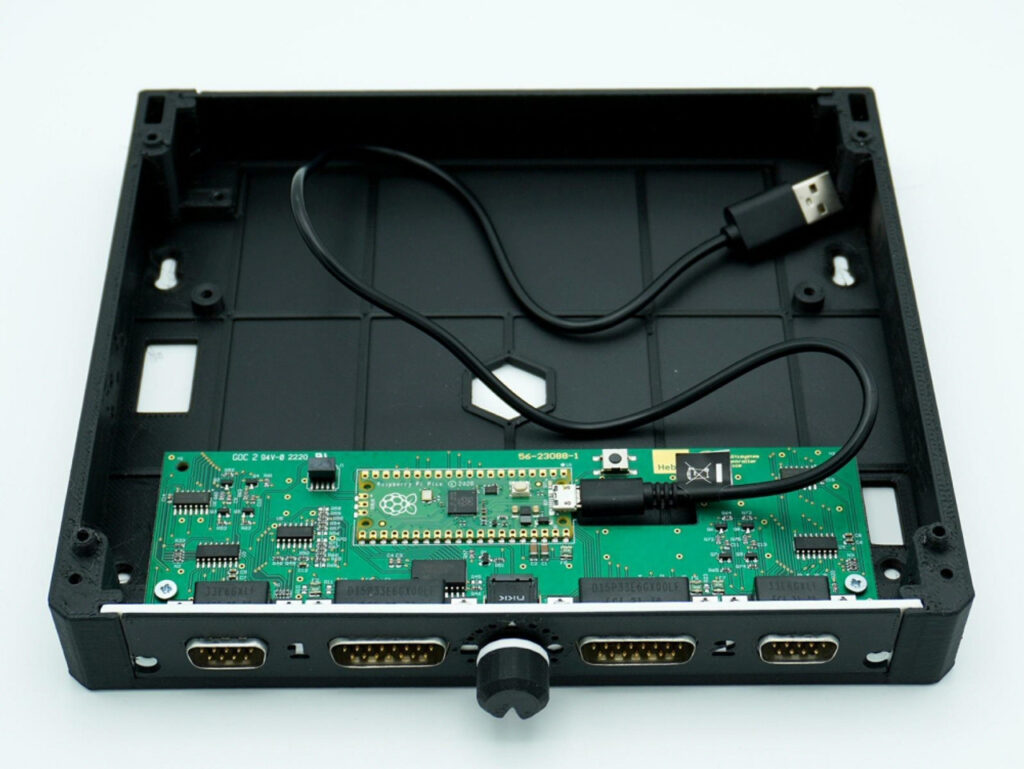

Since 1984 we have sold more than 1.5million electronic gaming control systems. Our controls are selected as the very heart of many gaming machines, amusements, fun games and arcades, used and trusted by manufacturers both large and small, all over the world.

We have a huge range of experience in video and gaming system controllers and consoles – from design to development, prototyping and manufacture. Our core capabilities include embedded real-time software and closed loop control systems, analogue signal measurement and conditioning, and Windows® embedded and Linux operating systems. We also work with FPGA gaming systems, DE10 nano boards and Raspberry Pi boards.ystems.

For our most recent gaming console hceck our the Mutlisystem Page .

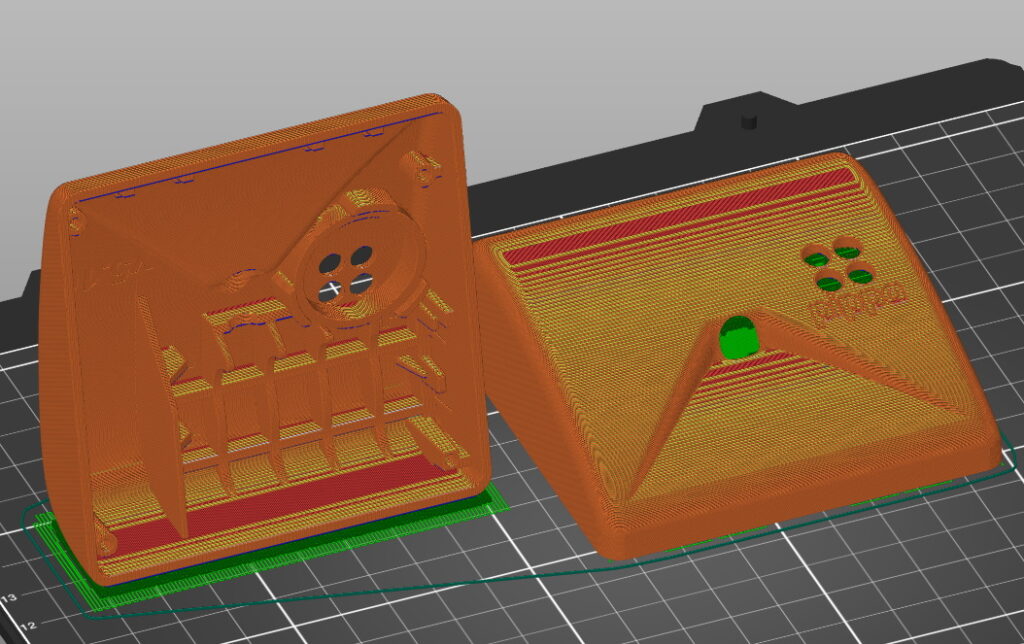

Enclosure Prototype and Concept Modelling

At Heber we are able to offer a bespoke 3D printing service, meaning we can not only create your electronics but also the enclosures for them. With 3D print projects we will work with you through the early design phases using specialised design software, right through to creating prototypes specifically made to your requirements.

The benefit of creating these prototypes is that they can be designed and manufactured specifically for one project. It is a great way to produce the perfect enclosure as any changes can be made quickly and at a low cost. Once the prototype has been finalised the digital model will allow for use in injection moulding, or 3D printing on a lager scale.

Why Heber?

Choosing Heber means choosing over 35 years of proven designs and industry benchmark products. We offer much more than just specialist technical engineering; our team understands the industry’s commercial drivers, too. The need for features to add real value to the product, the economics of manufacturing costs, the importance of superior customer support. We can assist with development, innovation or consultancy on your project, even if it just some problem-solving advice you need.

These are just some of the reasons why manufacturers, from large companies to start ups rely on Heber’s expertise:

- Real-time PC-based and embedded control systems

- Off-the-shelf range in any volume with worldwide supply

- Custom or semi-custom products for medium to high volumes

- Cost-sensitive projects

- Fast time-to-market

- Innovative solutions at low cost

- Flexible relationships & joint-venture partnerships

- A ‘can-do’ and transparent approach

To discover all our concept product ideas and discuss the use of already developed IP or new IP in one of your products, please contact us.